Food

Reliable and safe drive solutions for the food industry

NORD DRIVESYSTEMS covers a wide range of food industry applications with industry-specific and innovative drive solutions.

We are familiar with your business and your requirements. We prefer long-term collaboration with our customers and partners. You can rely on us! Together with you we will do everything we can to further strengthen your brand’s reputation.

NORD DRIVESYSTEMS provides:

- Extensive application knowledge and technical support

- Complete drive solutions from a single source

- Strong global presence and service

- Thousands of installed drives in the food and beverage industry

- Wide range of products with high quality standards

- Great reliability, economy and service life

- Recognised production quality compliant with international standards

Reliability in the food industry

IE5+ synchronous motor (TENV)

High-efficiency synchronous motor with hygienic design

NORDAC ON / ON+ SK 300P

Decentralised frequency inverter

NORDBLOC.1 Helical Bevel Gear Motor

Helical bevel gear unit with housing made of high-strength aluminium alloy

UNIVERSAL SMI Worm Gear Unit

Worm gear unit with hygienic design

NORDBLOC.1 Helical Inline Gear Motor

Helical Inline Gear Unit with hygienic design

UNICASE Helical Bevel Gear Motor

Helical bevel gear unit with robust housing and high ratio

UNICASE Parallel Gear Motor

Gear motor with slim design

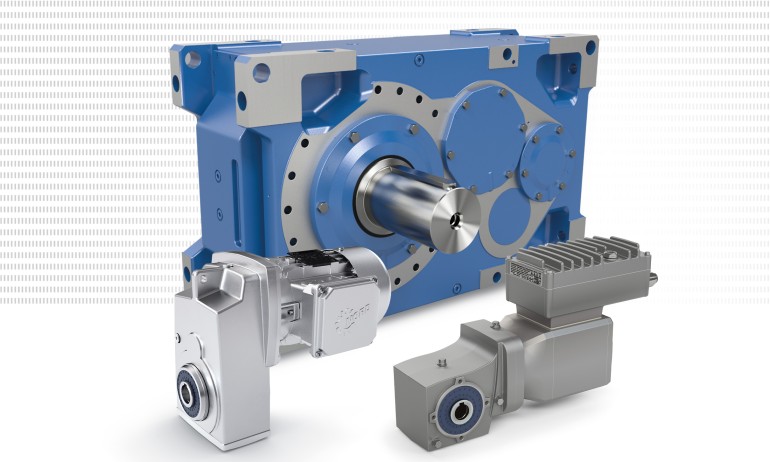

MAXXDRIVE® XC parallel gear unit

Industrial gear unit with compact, modular design

NORDAC BASE - SK 180E - Frequency Inverter

Decentralised frequency inverter

NORDAC PRO - SK 500P - Frequency Inverter

Frequency inverter for control cabinet installation

Arnreiter

驱动系统为粮食加工厂提供输送动力

防爆诺德驱动器为Arnreiter Mühle GmbH工厂的谷物和种子加工提供支持。它们可靠地连续运行驱动输送和分配系统。

Baader Group

复杂分离技术

BAADER集团为食品工业开发分离器已超过40年。其产品范围包括使用诺德斜齿伞齿轮减速电机坚固驱动齿链的压力分离器。

德国特莱富 (Treif) 公司食品加工

智能切片

Treif Maschinenbau GmbH是先进的食品切割设备制造商之一。为实现高度的灵活性,这家设备制造商依赖于诺德的驱动技术。

Jütro精品食品

智能、平衡、稳定:驱动技术确保安全运行

2021年,Jütro与NORD DRIVESYSTEMS及其他合作伙伴共同建立了一座新的PET瓶装生产线,其中减速电机、变频器及应用技术发挥了核心作用。

Zotter

坚固耐用的驱动系统展现自己甜美的一面

诺德驱动器在Zotter巧克力工厂可靠、安全地执行搅拌、输送、填装和其他作业。