Beverage

Complete drive solutions from a single source

NORD DRIVESYSTEMS covers a wide range of applications in the beverage industry with industry-specific, innovative drive solutions.

We know your business and precisely understand your requirements. We prefer long-term collaboration with our customers and partners. You can be confident that we will do everything that we can to reinforce the good reputation of your brand.

NORD DRIVESYSTEMS provides:

- Extensive knowledge of applications and technical support

- Complete drive solutions from a single source

- Strong global presence and service

- Thousands of installed drives in the food and beverage industry

- Wide range of products with high quality standards

- Great reliability, economy and service life

- Recognised product quality compliant with international standards

- Power range: 0.35–3.0 kW

- Extremely high system efficiency

- Compact installation space for flexible use

- Wash-down design with NXD tupH surface treatment for the most stringent hygiene requirements

- System solution for simple commissioning and plug & play

IE5+ synchronous motor (TENV)

High-efficiency synchronous motor with hygienic design

- 0.35 kW - 2.2 kW

- IP69K (optional)

- Worldwide approvals and acceptance

- Compact and hygienic design, available with NXD tupH® for food-safe surface protection

- Constant high efficiency over the entire adjustment range

NORDAC ON / ON+ SK 300P

Decentralised frequency inverter

- Power range: 0.37 - 3.7 kW

- Protection class: IP55, IP66

- Versatile use with wall or motor mounting

- Simple integration via multi-protocol Ethernet interface

- Fast plug-and-play commissioning

UNIVERSAL SMI Worm Gear Unit

Worm gear unit with hygienic design

- 0.12 kW - 4.0 kW

- 21 Nm - 427 Nm

- Wash-down capable, available with NXD tupH® for food-safe surface protection

- Low noise levels thanks to quiet running

- Low space requirement thanks to compact design

NORDBLOC.1 Helical Bevel Gear Motor

Helical bevel gear unit with housing made of high-strength aluminium alloy

- 0.12 kW - 9.2 kW

- 50 Nm - 660 Nm

- High radial and axial load capacity ensures safe operation

- Wash-down capable, available with NXD tupH® for food-safe surface protection

- Lightweight thanks to aluminum housing

NORDBLOC.1 Helical Inline Gear Motor

Helical Inline Gear Unit with hygienic design

- 0.12 kW - 37 kW

- 30 Nm - 3,300 Nm

- Wash-down capable, available with NXD tupH® for food-safe surface protection

- Low weight thanks to aluminum housing

- Low noise levels thanks to quietrunning

UNICASE Helical Bevel Gear Motor

Helical bevel gear unit with robust housing and high ratio

- 0.12 kW - 200 kW

- 180 Nm - 50,000 Nm

- High power density

- Low maintenance with long service life

- High radial and axial loads

UNICASE Parallel Gear Motor

Gear motor with slim design

- 0.12 kW - 200 kW

- 110 Nm - 100,000 Nm

- Slim design for space-saving installation

- Wash-down capable, can be equipped with NXD tupH® for food-safe surface protection

- Low noise levels thanks to quiet running

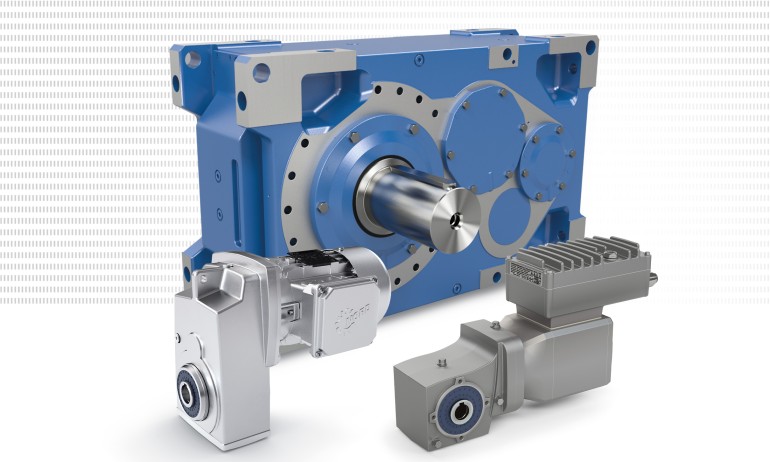

MAXXDRIVE® XC parallel gear unit

Industrial gear unit with compact, modular design

- Power range: 1.5 kW–6,000 kW

- Torque: 15,000 Nm- 282,000 Nm

- XC means eXtra Compact

- Modular design for tailor-made drive solutions

- Low-noise operation

NORDAC BASE - SK 180E - Frequency Inverter

Decentralised frequency inverter

- Power range: 0.25 – 2.2 kW

- Protection class: IP55, IP66

- Versatile use with wall or motor mounting

- Economic dimensioning with functional basic equipment

- Low space requirements thanks to compact size

NORDAC PRO - SK 500P - Frequency Inverter

Frequency inverter for control cabinet installation

- Power range: 0.25 kW – 37 kW (up to 160 kW in preparation)

- Protection class: IP20

- Simple system integration via multi-protocol Ethernet interface

- Fast commissioning due to voltage-free parameterisation via USB port

- Multiple axis operation controllable via multi-encoder interface

Wild Goose Canning公司与诺德公司密切合作,共同开发和生产用于饮料行业的灌装设备。诺德公司高质量的坚固减速电机令人印象深刻。

可靠的驱动器和一流的客户服务是诺德为设备制造商G.C Evans提供的众多优势中的两个。

对于Octopi啤酒厂(美国),诺德提供的采用特殊表面处理的驱动器符合了精酿啤酒厂的要求。通过表面处理技术,这些驱动器具有较高的耐腐蚀性能。

Forst专业啤酒厂高效地连续生产。为了确保研磨机、输送系统和搅拌机不会出现故障,啤酒厂选择使用可靠的诺德减速电机。

TMCI是食品和饮料行业的先进机器制造商。TMCI与诺德合作开发了一个新型过滤设备,更易于清洗并且可以更好地保留风味。

开发细微的味道差别需要复杂的生产过程。机器连续运行。为了防止中断,MOPOS安装了可靠的诺德驱动器。